Manufacturing

Manufacturing facilities rely on water throughout their plant and processes. Whether water is a key ingredient in your production or heats and cools your equipment, you need your water to be at its best.

Protecting all mechanical systems.

Self-cleaning strainers installed at the point-of-entry to the facility (DCW main) remove all of the physical dirt and turbidity that comes in through the water main. This protects every single mechanical component ultimately connected to the water system - pumps, seals, valves, boilers, heat exchangers, washers, flushometers, PRVs, filters, medical device reprocessing, etc. Due to the high investment in mechanical infrastructure in a manufacturing plant, the return on investment on these systems is often under a year. There are thousands of these systems operating in North America today.

Next generation sidestream Filters for closed-loop.

Still throwing away money and dirty sidestream filters? The next generation of sidestream filters are here, which are cleaned in place in less than one minute with no disassembly required. No replacement parts means no maintenance costs. Massive savings in time and parts compared to the traditional throw-away models.

Purified water for your most critical ingredient

Water is the most important ingredient for many food and beverage applications. Bottled water systems, beer brewing, supplements and various sub-ingredients, food products and more all need perfect water to perfect their products. Common purification needs are as follows:

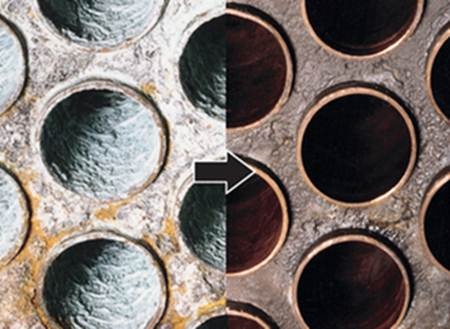

Eliminate scaling on boilers.

Even small levels of hardness and scaling-causing minerals in your water can have massive costs and downtime associated with it. As the small concentrations in the make-up water are magnified over time in a recirculating system, premature mechanical failure and a huge loss in heat exchange efficiency leads to expensive and unnecessary costs.

Some amazing manufacturers we've helped

Need help with a water problem?

Send us a message here, or call us at (604) 630-1114 (Vancouver) or (250) 412-1110 (Victoria)

Expertise

Mechanical protection

Potable Water Systems

Rainwater Harvesting

High-Purity Water

© 2025 Tiger Purification Systems Inc (Watertiger)